Customizes the economic information you want to receive by sections.[Subscribe]

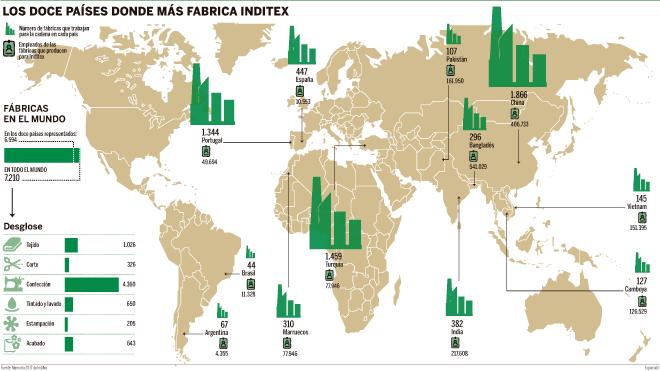

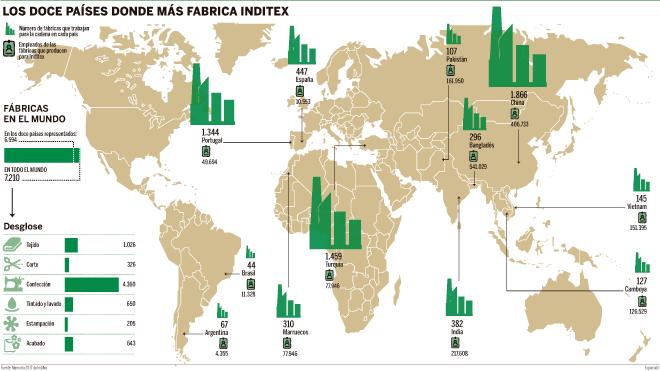

The firm works with a network of 7.210 factories concentrated in twelve clusters to execute a business model that seeks to respond quickly to the market.

The process is vertiginous.Only one hour after any Zara manager in the world plays a merchandise, the group's center analyzes its stock and the needs to give green light to the same.At two hours, the logistics area begins to prepare it, and in eight hours it has already left the warehouse.The company distributes orders to any of its world stores in a maximum of 48 hours, regardless of whether they are located in Malaga or Australia.

Few global companies have at the same time a production structure as centralized as Inditex.The Spanish textile giant sells more than 65.000 references a year in its more than 7.500 stores located in 96 countries.But, in the face of this, the group concentrates the creation of its products -through its more than 700 designers -, the manufacture of them -95% occurs in 12 countries -and their logistics system -all the garments pass throughone of its 12 stores in Spain-.

The productive structure with which Inditex works responds to its business model, which is based on flexibility to quickly respond to the market in an integrated way, both in store and online.Although each of its brands creates a collection per season, much of the success of the chain is its reaction capacity in record time: it takes less than three weeks since it detects a trend until it takes the products to its stores that respond toshe.That translates into a great capacity to constantly renew the offer of establishments, twice a week.

Does it make sense to produce in China and bring the product to Spanish logistics warehouses if it is going to be sold in China?In the Inditex model, yes.The company, which only has 10 own factories in Arteixo (A Coruña), works with 7.210 plants in the world in a non -exclusive way that produce all their designs, but 95% of everything the company sells is made in just 12 countries: Spain, Portugal, Morocco, Turkey, India, Pakistan Bangladés, Vietnam, Cambodia, China, Argentina and Brazil.

I Don’t Know How To Even Start My Day Properly.I’ve Written A FEW ARTICLES AND NOT EVENT TOUED MY COFFEE.I’m not ... https: // t.CO/HM8QNOFSRB

— 💙🧡Cierra (Hoodie Lindor)⚾️☕️ Fri Apr 16 17:17:30 +0000 2021

China is the country with more factories that work for Inditex, with a total of 1.866 plants that give employment to 406.733 people, followed by Turkey, with 1.459 factories, and Portugal, with 1.344.For its part, although in Bangladés it only has agreements with 296 factories, these are larger than those of other countries and give work to more than 540.000 people.

The numbers are important, but even more the philosophy behind them.The group has generated production clusters in these twelve countries that group suppliers, manufacturers and brands.It is about creating a work ecosystem in which the entire supply chain works jointly, coordinated and in a flexible way.

For example, 57% of Inditex's production is grouped into what the company calls closeness (Spain, Portugal, Morocco and Turkey).It is in these nearby countries where the most associated articles are produced to trends and preparation, which favors that the group can quickly react to their store needs, while other more basic products and that they will not be so affectedSo it becomes fashionable at all times are made in farther markets.

Concentration is not only geographical but also productive.Each cluster specializes in different types of products, materials or elaboration methods, which increases efficiency.Of 7.210 factories that work for unclocurious to indinditex, the main ones in number are those of clothing (4.360), followed by fabrics (1.026), Tinta and washing (650), finish (643), cut (326) and stamping (205).

Finally, the concentration of factories and suppliers with which the textile chain works has a final added benefit: it makes them easier to control them.The group has more than 3.000 people, entre internas y externas, dedicadas a examinar los criterios de sostenibilidad, calidad y condiciones de trabajo que Inditex exige a sus socios.Although they do not work exclusively for the company, the textile group requires the 1.760 suppliers and 7.210 factories with which they collaborate that they fulfill their code of conduct and agreements in all types of subjects.

Inditex last year 4.215 Social Audits to its partners to verify whether they meet that code, in addition to another 2.159 in terms of health and safety and 2.621 traceability.All these controls are monitoring, since before starting working with any partner, another type of audits, calls from pre-assement, without notice, to evaluate the suitability or not to incorporate that company in the Inditex ecosystem are carried out.

The company stopped working last year, for example, with 33 suppliers for not fulfilling its code of conduct, more than the 31 that ruled out for commercial reasons.The result is that 95% of their purchases are already made to suppliers with a rating A or B in sustainability criteria.The objective is 100%.